規格

| 1 簡介 | |||||

|

Introduction

法蘭 (Flange),又叫法蘭凸緣盤或突緣。法蘭是管道與管道之間相互連接的零件,用於管端之間的連接;也有 用在設備進出口上的法蘭,用於兩個設備之間的連接,如減速機法蘭。法蘭連接或法蘭接頭,是指由法蘭、墊 片及螺栓三者相互連接作為一組組合密封結構的可拆連接。管道法蘭係指管道裝置中配管用的法蘭,用在設備 上係指設備的進出口法蘭。法蘭上有孔眼,螺栓使兩法蘭緊連。法蘭間用襯墊密封。法蘭分螺紋連接法蘭、焊 接法蘭和卡夾法蘭。法蘭都是成對使用的,兩片法蘭盤之間加上密封墊片,然後用螺栓緊固。不同壓力的法蘭 厚度不同,它們使用的螺栓也不同。水泵和閥門,在和管道連接時,這些器材設備的局部,也製成相對應的法 蘭形狀,也稱為法蘭連接。凡是在兩個平面周邊使用螺栓連接同時封閉的連接零件,一般都稱為“ 法蘭 ”。 |

|||||

|

|

|||||

| 2 法蘭標準 | |||||

|

Flanges Standard

美標:ANSI B16.5、ANSI 16.47 Class 150, 300, 400, 600, 900, 1500, 2500 日標:JIS 5K, 10K, 16K, 20K 德標:DIN2527, 2543, 2545, 2566 2572, 2573, 2576, 2631, 2632, 2633 , 2634, 2638 |

|||||

|

|

|||||

| 3 法蘭型式 | |||||

|

Flanges Standard

- SO 滑套法蘭 SLIP-ON Flanges - SC 絲口法蘭 SCREWED Flange - SW 套焊法蘭 SOCKET WELDING Flange - WN 焊頸法蘭 WELDING NECK Flange - LJ 鬆套法蘭 LAP JOINT Flange - BL 盲法蘭 BLIND Flange - PL 平法蘭 PLATE Flange |

|||||

|

|

|||||

| 4 法蘭密封面 | |||||

|

Flanges Sealing Surface

- RF 凸面 Raise Face - FF 平面 Flat Face |

|||||

|

|

|||||

| 5 法蘭材質 | |||||

|

Flanges Material

- 碳鋼 Carbon Steel:ASTM A105、 ASTM A350 LF1, LF2, LF3 - 不銹鋼 Stainless Steel:ASTM A182 F304, 304L, F316, 316L, 304H, 310, 321, 347, 348 - 合金鋼 Alloy Steel:ASTM A182 F1, F2, F5, F5a, F9, F11, F12, F21, F22 |

|||||

|

|

|||||

| 6 Ring Joint Facing | |||||

|

Depth L ⋯ + 1/64-0 inch

Width F ⋯ ± 0.008 inch

Pitch Diameter P ⋯ ± 0.005 inch Radius at Bottom r ⋯ max 23° angle ⋯ ± 1/2° |

|||||

|

|

|||||

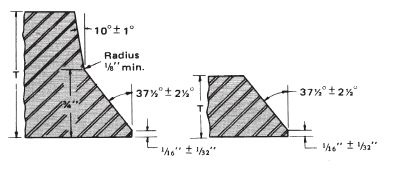

| 7 Welding Bevels | |||||

|

Butt welding ends having thicknesses (T) less than 3/16 inch

may have a slight chamfer or be square; thicknesses of 3/16 to 3/4 inch inclusive shall be beveled 371/2° and the root face (land) shall be 1/16 inch; thicknesses greater than 3/4 inch shall be beveled 371/2° with the thickness beyond 3/4 inch beveled 10°. |

|||||

|

|

|||||

| 8 Orifice Flange | |||||

|

For orifice flanges (not covered by ANSI B16.5) the usual

tolerance on the dimensions 15/16 inch from gasket surface to meter connection tap is ± 1/64 inch for sizes 3 inch and smaller, ± 1/32 inch for sizes 4 inch and larger; regular flange tolerances apply to all other dimensions expect bore tolerances which are 1/2 of 1 percent of nominal bore size. |

|||||

|

|

|||||

詳細介紹

| Thread, Slip-on, Lap Joint,Socket Welding and Blind | |||||

| Outside Diameter* | O.D. 24 inch or smaller ⋯ ±1/16 inch | ||||

| O.D. over 24 inch ⋯ ±1/8 inch | |||||

| Inside Diameter (bore) |

threaded: to standard gauge limits Slip-on; Lap joint; Socket-welding |

||||

| 10 inch and smaller ⋯ +1/32-0 inch | |||||

| 12 inch and smaller ⋯ +1/16-0 inch | |||||

| Diameter counter bore |

threaded | ||||

| 10 inch and smaller ⋯ +1/32-0 inch | |||||

| 12 inch and large ⋯ +1/16-0 inch | |||||

| Outside Diameter of Hub * |

12 inch and smaller ⋯ +3/32-1/16 inch | ||||

| 14 inch and large ⋯ ±1/8 inch | |||||

| Diameter of contact face |

1/16 inch raised face; 1/4 inch raised face; tongue & grooved |

||||

| Male & Female ⋯ ±1/64 inch | |||||

| Thickness | 18 inch and smaller ⋯ +1/8-0 inch | ||||

| 20 inch and large ⋯ +3/16-0 inch | |||||

| Length Through Hub* |

18 inch and smaller ⋯ +1/8-1/32 inch | ||||

| 20 inch and large ⋯ +3/16-1/16 inch | |||||

| Drilling* | bolt circle ⋯ ±1/16 inch | ||||

| bolt hole spacing ⋯ ±1/32 inch | |||||

| Eccentricity with respectto bore ⋯ 1/32 inch maximum |

|||||

| Welding Neck | |||||

| Outside Diameter* | O.D. 24 inch or smaller ⋯ ±1/16 inch | ||||

| O.D. over 24 inch ⋯ ±1/8 inch | |||||

| Inside Diameter (bore) |

10 inch and smaller ⋯ ±1/32 inch | ||||

| 12 through 18 inch ⋯ ±1/16 inch | |||||

| 20 inch and large ⋯ +1/8-1/16 inch | |||||

| Diameter counter bore |

1/16 inch raised face; 1/4 inch raised face; tougue & grooved |

||||

| Male & Female ⋯ ±1/64 inch | |||||

| Diameter of Hub at Base* |

when x is 24 inch or smaller ⋯ ±1/16 inch | ||||

| when x is over 24 inch ⋯ ±1/8 inch | |||||

| Diameter of Hub at Point of Welding |

5 inch and smaller ⋯ +3/32-1/32 inch | ||||

| 6 inch and large ⋯ +5/32-1/32 inch | |||||

| Thickness | 18 inch and smaller ⋯ +1/8-0 inch | ||||

| 20 inch and large ⋯ +3/16-0 inch | |||||

| Length Through Hub* |

10 inch and smaller ⋯ ±1/16 inch | ||||

| 12 inch and large ⋯ ±1/8 inch | |||||

| Drilling* | bolt circle ⋯ ±1/16 inch | ||||

| bolt hole spacing ⋯ ±1/32 inch | |||||

| Eccentricity with respect to bore ⋯ 1/32 inch maximum |

|||||

| * Not Covered by ANSI B16.5 | |||||

|

Unit Pound And (kg)

|

|||||||||||||||||

| Specification or stadards designation |

Symbol | Chemical Requirements | Mechanical Requirements | ||||||||||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | V | Nb | Cu | T.S. | Y.S. | EL. | RED. | HB | ||

| min. | min. | min. | min. | min. | |||||||||||||

| % | % | % | % | % | % | % | % | % | % | % | psi | psi | % | % | max. | ||

| A105 | Max. 0.35 |

Max. 0.60 1.05 |

Max. 0.040 |

Max. 0.050 |

Max. 0.35 |

Max. 0.40 |

Max. 0.30 |

Max. 0.12 |

Max. 0.03 |

Max. 0.02 |

Max. 0.40 |

70,000 | 36,000 | 22 | 30 | 137 ~187 |

|

| A181 | I | 0.35 | 1.10 | 0.050 | 0.050 | 0.35 | 60,000 | 30,000 | 22 | 35 | |||||||

| A181 | I1 | 0.35 | 1.10 | 0.050 | 0.050 | 0.35 | 70,000 | 36,000 | 18 | 24 | |||||||

| A182 | F1 | 0.28 | 0.60 ~0.90 |

0.045 | 0.045 | 0.15 ~0.35 |

0.44 ~0.65 |

70,000 | 40,000 | 25 | 35 | 143 ~192 |

|||||

| A182 | F2 | 0.21 | 0.30 ~0.80 |

0.040 | 0.040 | 0.10 ~0.60 |

0.50 Max |

0.50 ~0.81 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 30 | 143 ~192 |

|||

| A182 | F5 | 0.15 | 0.30 ~0.60 |

0.030 | 0.030 | 0.50 | 0.50 Max |

4.00 ~6.00 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 35 | 143 ~217 |

|||

| A182 | F5a | 0.25 | 0.60 | 0.040 | 0.030 | 0.50 | 4.00 ~6.00 |

0.44 ~0.65 |

90,000 | 65,000 | 22 | 50 | 187 ~248 |

||||

| A182 | F9 | 0.15 | 0.30 ~0.60 |

0.030 | 0.030 | 0.50 ~1.00 |

8.00 ~10.00 |

0.90 ~1.10 |

85,000 | 55,000 | 20 | 40 | 179 ~207 |

||||

| A182 | F11 | 0.10 ~0.20 |

0.30 ~0.80 |

0.040 | 0.040 | 0.05 ~1.00 |

1.00 ~1.50 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 30 | 143 ~207 |

||||

| A182 | F12 | 0.10 ~0.20 |

0.30 ~0.80 |

0.040 | 0.040 | 0.10 ~0.60 |

8.00 ~10.00 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 30 | 143 ~207 |

||||

| A182 | F21 | 0.15 | 0.30 ~0.60 |

0.040 | 0.040 | 0.50 | 2.65 ~3.35 |

0.80 ~1.06 |

75,000 | 45,000 | 20 | 30 | 156 ~207 |

||||

| A182 | F22 | 0.15 | 0.30 ~0.60 |

0.040 | 0.040 | 0.50 | 2.00 ~2.50 |

0.87 ~1.13 |

75,000 | 45,000 | 20 | 30 | 156 ~207 |

||||

| A182 | F304 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 8.00 ~11.00 |

18.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F304H | 0.04 ~0.10 |

2.00 | 0.040 | 0.030 | 1.00 | 8.00 ~11.00 |

18.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F304L | 0.035 | 2.00 | 0.040 | 0.030 | 1.00 | 8.00 ~13.00 |

18.00 ~20.00 |

70,000 | 25,000 | 30 | 50 | |||||

| A182 | F310 | 0.15 | 2.00 | 0.040 | 0.030 | 1.00 | 19.00 ~20.00 |

24.00 ~26.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F316 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 10.00 ~14.00 |

16.00 ~18.00 |

2.00 ~3.00 |

75,000 | 30,000 | 30 | 50 | ||||

| A182 | F316H | 0.04 ~0.10 |

2.00 | 0.040 | 0.030 | 1.00 | 10.00 ~14.00 |

16.00 ~18.00 |

2.00 ~3.00 |

75,000 | 30,000 | 30 | 50 | ||||

| A182 | F316L | 0.035 | 2.00 | 0.040 | 0.030 | 1.00 | 10.00 ~15.00 |

16.00 ~18.00 |

2.00 ~3.00 |

70,000 | 25,000 | 30 | 50 | ||||

| A182 | F321 | 0.08 | 2.00 | 0.030 | 0.030 | 1.00 | 9.00 ~12.00 |

17.00 ~Min. |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F347 | 0.08 | 2.00 | 0.030 | 0.030 | 1.00 | 9.00 ~13.00 |

17.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F348 | 0.08 | 2.00 | 0.030 | 0.030 | 1.00 | 9.00 ~13.00 |

17.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A350 | LF1 | 0.30 | 0.75 ~1.05 |

0.035 | 0.040 | 0.15 ~0.30 |

60,000 ~85,000 |

30,000 | 25 | 38 | |||||||

| A350 | LF2 | 0.30 | 1.35 | 0.035 | 0.040 | 0.15 ~0.30 |

70,000 ~95,000 |

36,000 | 22 | 30 | |||||||

| A350 | LF3 | 0.20 | 0.90 | 0.035 | 0.040 | 0.20 ~0.35 |

3.25 ~3.75 |

70,000 ~95,000 |

37,500 | 22 | 35 | ||||||

|

Unit Pound And (kg)

|

|||||||

| Class | Nominal Pipe Size |

Slip on Type | Blind | Welding Neck |

|||

| Slip On | Screwed | Socket | Lap Joint | ||||

| 150 lb | 1/2 | 1 (0.45) | 1 (0.45) | 2 (0.91) | 2 (0.91) | 2 (0.91) | 2 (0.91) |

| 3/4 | 11/2 (0.68) | 11/2 (0.68) | 2 (0.91) | 21/2 (0.91) | 2 (0.91) | 2 (0.91) | |

| 1 | 2 (0.91) | 2 (0.91) | 2 (0.91) | 2 (0.91) | 2 (0.91) | 21/2 (1.41) | |

| 11/4 | 21/2 (1.41) | 21/2 (1.41) | 3 (1.36) | 31/2 (1.36) | 3 (1.36) | 21/2 (1.41) | |

| 11/2 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 4 (1.81) | |

| 2 | 5 (2.18) | 5 (2.27) | 5 (2.27) | 5 (2.27) | 4 (1.82) | 6 (2.72) | |

| 21/2 | 8 (3.45) | 8 (3.45) | 7 (3.18) | 8 (3.63) | 7 (3.18) | 10 (4.45) | |

| 3 | 9 (4.01) | 10 (4.54) | 8 (3.63) | 9 (4.09) | 9 (4.09) | 111/2 (5.22) | |

| 31/2 | 11 (4.99) | 12 (5.45) | 11 (4.99) | 11 (4.99) | 13 (5.90) | 12 (5.45) | |

| 4 | 13 (5.63) | 13 (5.9) | 13 (5.90) | 13 (5.90) | 17 (7.72) | 161/2 (7.49) | |

| 5 | 15 (6.74) | 15 (6.81) | 15 (6.81) | 15 (6.81) | 20 (9.08) | 21 (9.53) | |

| 6 | 17 (7.90) | 191/2 (8.85) | 19 (8.63) | 19 (8.63) | 27 (12.26) | 26 (11.80) | |

| 8 | 28 (12.90) | 30 (13.62) | 30 (13.62) | 30 (13.62) | 47 (21.34) | 42 (19.07) | |

| 10 | 40 (17.60) | 41 (18.61) | 43 (19.52) | 43 (19.52) | 67 (30.42) | 54 (24.52) | |

| 12 | 61 (27.69) | 65 (29.51) | 64 (29.06) | 64 (29.06) | 123 (45.00) | 88 (39.95) | |

| 14 | 83 (37.68) | 85 (38.59) | 85 (38.59) | 99 (44.95) | 139 (63.11) | 114 (51.76) | |

| 16 | 106 (48.12) | 93 (42.22) | 93 (42.22) | 128 (58.11 | 187 (84.90) | 142 (64.47) | |

| 18 | 109 (49.49) | 120 (54.48) | 120 (54.48) | 146 (66.28) | 217 (98.52) | 165 (74.90) | |

| 20 | 148 (67.19) | 155 (70.37) | 155 (70.37) | 185 (83.99) | 283 (128.48) | 197 (89.44) | |

| 24 | 204 (92.62) | 210 (95.34) | 210 (95.34) | 260 (118.04) | 415 (188.41) | 268 (121.67) | |

| 300 lb | 1/2 | 11/2 (0.68) | 11/2 (0.68) | 3 (1.36) | 3 (1.36) | 2 (0.91) | 2 (0.91) |

| 3/4 | 21/2 (1.14) | 21/2 (1.14) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | |

| 1 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 4 (1.82) | 4 (1.82) | |

| 11/4 | 41/2 (2.04) | 41/2 (2.04) | 4 (1.82) | 41/2 (2.04) | 6 (2.72) | 5 (2.72) | |

| 11/2 | 61/2 (2.95) | 61/2 (2.95) | 6 (2.72) | 61/2 (2.95) | 7 (3.18) | 7 (3.18) | |

| 2 | 7 (3.18) | 7 (3.18) | 7 (3.18) | 7 (3.18) | 8 (3.63) | 8 (3.63) | |

| 21/2 | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | 12 (5.45) | 12 (5.45) | |

| 3 | 13 (5.90) | 14 (6.36) | 13 (5.90) | 141/2 (6.58) | 16 (7.26) | 18 (8.17) | |

| 31/2 | 16 (7.26) | 16 (7.26) | 17 (7.72) | 17 (7.72) | 21 (9.53) | 20 (9.1) | |

| 4 | 231/2 (10.67) | 24 (10.90) | 22 (9.99) | 24 (10.90) | 28 (12.71) | 261/2 (12.03) | |

| 5 | 29 (13.17) | 31 (14.07) | - | 28 (12.71) | 37 (16.80) | 36 (16.34) | |

| 6 | 36 (16.34) | 36 (16.34) | - | 39 (17.71) | 48 (21.79) | 45 (20.43) | |

| 8 | 56 (25.42) | 56 (25.42) | - | 58 (26.33) | 79 (35.87) | 69 (31.33) | |

| 10 | 77 (34.96) | 80 (36.32) | - | 91 (41.31) | 122 (55.39) | 100 (45.4) | |

| 12 | 113 (51.30) | 110 (49.94) | - | 139 (63.11) | 183 (83.08) | 142 (64.47) | |

| 14 | 159 (72.19) | 164 (74.46) | - | 189 (85.81) | 241 (109.41) | 206 (93.52) | |

| 16 | 210 (95.34) | 220 (99.88) | - | 240 (108.96) | 315 (143.01) | 249 (113.05) | |

| 18 | 253 (114.86) | 280 (127.12) | - | 305 (138.47) | 414 (187.96) | 306 (138.92) | |

| 20 | 307 (139.38) | 325 (147.55) | - | 375 (170.25) | 515 (233.81) | 369 (167.53) | |

| 24 | 490 (222.46) | 490 (222.46) | - | 530 (240.62) | 800 (363.2) | 519 (235.63) | |

|

Unit Pound And (kg)

|

||||||

| Class | Nominal Pipe Size |

Slip on Type | Blind | Welding Neck |

||

| Slip On | Screwed | Lap Joint | ||||

| 400 lb | 1/2 | 2 (0.91) | 2 (0.91) | 3 (1.36) | 2 (0.91) | 3 (1.36) |

| 3/4 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 31/2 (1.59) | |

| 1 | 31/2 (1.59) | 31/2 (1.59) | 4 (1.82) | 4 (1.82) | 4 (1.82) | |

| 11/4 | 41/2 (2.04) | 41/2 (2.04) | 6 (2.72) | 6 (2.72) | 51/2 (2.50) | |

| 11/2 | 61/2 (2.95) | 61/2 (2.95) | 7 (3.18) | 8 (3.63) | 8 (3.63) | |

| 2 | 8 (3.63) | 8 (3.63) | 9 (4.09) | 10 (4.54) | 10 (4.54) | |

| 21/2 | 12 (5.45) | 12 (5.45) | 12 (5.45) | 15 (6.81) | 14 (6.36) | |

| 3 | 15 (6.81) | 15 (6.81) | 15 (6.81) | 20 (9.08) | 18 (8.17) | |

| 31/2 | 21 (9.53) | 21 (9.53) | 20 (9.08) | 29 (13.17) | 26 (11.80) | |

| 4 | 24 (10.9) | 24 (10.9) | 25 (11.35) | 33 (14.98) | 30 (13.62) | |

| 5 | 31 (14.07) | 31 (14.07) | 29 (13.17) | 44 (19.98) | 39 (17.71) | |

| 6 | 39 (17.71) | 39 (17.71) | 42 (19.07) | 61 (27.69) | 49 (22.45) | |

| 8 | 63 (28.60) | 63 (28.60) | 64 (29.06) | 100 (45.4) | 78 (35.41) | |

| 10 | 91 (41.31) | 91 (41.31) | 112 (50.85) | 155 (70.37) | 110 (49.94) | |

| 12 | 129 (58.57) | 129 (58.57) | 152 (69.01) | 226 (102.60) | 160 (72.64) | |

| 14 | 191 (86.71) | 191 (86.71) | 210 (95.34) | 310 (140.74) | 233 (105.78) | |

| 16 | 253 (114.86) | 253 (114.86) | 280 (127.12) | 398 (180.69) | 194 (133.78) | |

| 18 | 310 (140.74) | 310 (140.74) | 345 (156.63) | 502 (227.91) | 360 (163.44) | |

| 20 | 378 (171.61) | 378 (171.61) | 420 (190.68) | 621 (281.93) | 445 (202.03) | |

| 24 | 539 (244.71) | 539 (244.71) | 615 (279.21) | 936 (424.94) | 640 (290.56) | |

| 600 lb | 1/2 | 2 (0.91) | 2 (0.91) | 3 (1.36) | 2 (0.91) | 3 (1.36) |

| 3/4 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 31/2 (1.59) | |

| 1 | 31/2 (1.59) | 31/2 (1.59) | 4 (1.82) | 4 (1.82) | 4 (1.82) | |

| 11/4 | 41/2 (2.04) | 41/2 (2.04) | 6 (2.72) | 6 (2.72) | 51/2 (2.50) | |

| 11/2 | 61/2 (2.95) | 61/2 (2.95) | 7 (3.18) | 8 (3.63) | 8 (3.63) | |

| 2 | 8 (3.63) | 8 (3.63) | 9 (4.09) | 10 (4.54) | 10 (4.54) | |

| 21/2 | 12 (5.45) | 12 (5.45) | 12 (5.45) | 15 (6.81) | 14 (6.36) | |

| 3 | 15 (6.81) | 15 (6.81) | 15 (6.81) | 20 (9.08) | 18 (8.17) | |

| 31/2 | 21 (9.53) | 21 (9.53) | 20 (9.08) | 29 (13.17) | 26 (11.80) | |

| 4 | 33 (14.98) | 33 (14.98) | 36 (16.34) | 41 (18.61) | 37 (16.80) | |

| 5 | 63 (28.60) | 63 (28.60) | 63 (28.60) | 68 (30.87) | 68 (30.87) | |

| 6 | 80 (36.32) | 80 (36.32) | 78 (35.41) | 86 (39.04) | 73 (33.14) | |

| 8 | 97 (44.04) | 97 (44.04) | 112 (50.85) | 139 (63.11) | 112 (50.85) | |

| 10 | 177 (80.36) | 177 (80.36) | 195 (88.53) | 231 (104.87) | 189 (85.81) | |

| 12 | 215 (97.61) | 215 (97.61) | 240 (108.96) | 295 (133.93) | 226 (102.60) | |

| 14 | 259 (117.59) | 259 (117.59) | 290 (131.66) | 378 (148.91) | 347 (157.54) | |

| 16 | 366 (166.16) | 366 (166.16) | 400 (181.6) | 527 (239.26) | 481 (218.37) | |

| 18 | 476 (216.10) | 476 (216.10) | 469 (212.93) | 665 (301.91) | 555 (251.97) | |

| 20 | 612 (277.85) | 612 (277.85) | 604 (274.22) | 855 (388.17) | 690 (313.26) | |

| 24 | 876 (397.70) | 876 (397.70) | 866 (393.16) | 1175 (533.45) | 977 (443.56) | |

|

Unit Pound And (kg)

|

||||||

| Class | Nominal Pipe Size |

Slip on Type | Blind | Welding Neck |

||

| Slip On | Screwed | Lap Joint | ||||

| 900 lb | 1/2 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 4 (1.82) | 7 (3.18) |

| 3/4 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 6 (2.72) | 7 (3.18) | |

| 1 | 71/2 (3.41) | 71/2 (3.41) | 9 (4.09) | 9 (4.09) | 81/2 (3.86) | |

| 11/4 | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | |

| 11/2 | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | |

| 2 | 22 (9.99) | 22 (9.99) | 25 (11.35) | 25 (11.35) | 24 (10.90) | |

| 21/2 | 36 (16.34) | 36 (16.34) | 35 (15.89) | 35 (15.89) | 36 (16.34) | |

| 3 | 31 (14.07) | 31 (14.07) | 20 (13.62) | 32 (14.53) | 29 (13.17) | |

| 4 | 53 (24.06) | 53 (24.06) | 51 (23.15) | 54 (24.52) | 51 (23.15) | |

| 5 | 83 (37.68) | 83 (37.68) | 81 (36.77) | 87 (39.50) | 86 (39.04) | |

| 6 | 108 (49.03) | 108 (49.03) | 105 (47.67) | 113 (51.30) | 110 (49.94) | |

| 8 | 172 (78.09) | 172 (78.09) | 188 (85.35) | 197 (89.44) | 187 (84.90) | |

| 10 | 245 (111.23) | 245 (111.23) | 277 (125.76) | 290 (131.66) | 268 (121.67) | |

| 12 | 326 (148.00) | 326 (148.00) | 371 (168.43) | 413 (187.50) | 372 (168.89) | |

| 14 | 380 (172.52) | 380 (172.52) | 397 (180.24) | 494 (224.28) | 567 (255.15) | |

| 16 | 459 (208.39) | 459 (208.39) | 488 (221.55) | 619 (281.03) | 685 (310.99) | |

| 18 | 647 (293.74) | 647 (293.74) | 670 (304.18) | 880 (399.52) | 924 (419.50) | |

| 20 | 792 (359.57) | 792 (359.57) | 868 (394.07) | 1107 (502.58) | 1164 (528.46) | |

| 24 | 1480 (671.92) | 1480 (671.92) | 1659 (753.19) | 2099 (952.95) | 2107 (956.58) | |

| 1500 lb | 1/2 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 4 (1.82) | 7 (3.18) |

| 3/4 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 6 (2.72) | 7 (3.18) | |

| 1 | 71/2 (3.41) | 71/2 (3.41) | 9 (4.09) | 9 (4.09) | 81/2 (3.86) | |

| 11/4 | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | |

| 11/2 | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | |

| 2 | 22 (9.99) | 22 (9.99) | 25 (11.35) | 25 (11.35) | 24 (10.90) | |

| 21/2 | 36 (16.34) | 36 (16.34) | 35 (15.9) | 35 (15.89) | 36 (16.34) | |

| 3 | 48 (21.79) | 48 (21.79) | 47 (21.3) | 48 (21.79) | 48 (21.79) | |

| 4 | 73 (33.14) | 73 (33.14) | 75 (34.05) | 73 (33.14) | 69 (31.33) | |

| 5 | 132 (59.93) | 132 (59.93) | 138 (62.65) | 142 (64.47) | 132 (59.93) | |

| 6 | 164 (74.46) | 164 (74.46) | 170 (77.18) | 159 (72.19) | 164 (74.46) | |

| 7 | 258 (117.13) | 258 (117.13) | 286 (129.84) | 302 (137.11) | 273 (123.94) | |

| 10 | 436 (197.94) | 436 (197.94) | 485 (220.19) | 507 (230.18) | 454 (206.12) | |

| 12 | 667 (302.82) | 667 (302.82) | 749 (340.05) | 775 (351.85) | 690 (313.26) | |

| 2500 lb | 1/2 | 7 (3.18) | 7 (3.18) | 7 (3.18) | 7 (3.18) | 8 (3.63) |

| 3/4 | 9 (4.09) | 9 (4.09) | 8 (3.63) | 10 (4.54) | 9 (4.09) | |

| 1 | 12 (5.45) | 12 (5.45) | 12 (5.45) | 12 (5.45) | 13 (5.90) | |

| 11/4 | 18 (8.17) | 18 (8.17) | 17 (7.72) | 18 (8.17) | 20 (9.08) | |

| 11/2 | 25 (11.35) | 25 (11.35) | 24 (10.90) | 25 (11.35) | 28 (12.71) | |

| 2 | 38 (17.25) | 38 (17.25) | 37 (16.80) | 39 (17.71) | 42 (19.07) | |

| 21/2 | 55 (24.97) | 55 (24.97) | 53 (24.06) | 56 (25.42) | 52 (23.61) | |

| 3 | 83 (37.68) | 83 (37.68) | 80 (36.32) | 86 (39.04) | 94 (42.68) | |

產品諮詢