Specification

| 1 Introduction | |||||

|

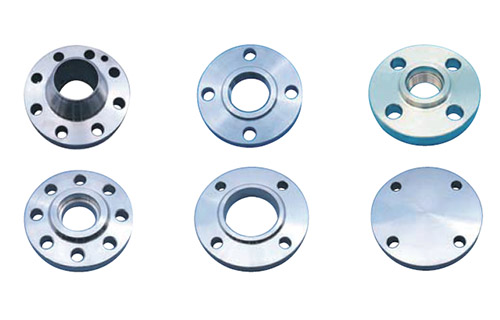

The flange is the part of the piping and the piping that is conn ected to each other for the connection

between the ends of the pipe. It is also used for the flange on the inlet and outlet of the device for the connection between two devices, such as the flange of the reduce r. A flange connection or a flange joint refers to a detachable connection in which a flange, a gas ket and a bolt are connected to each other as a combined sealing structure. Pipe flange refers to the flange used for piping in the pipeline installation. It is used on the equipment to refer to the inlet and outlet flanges of the equipment. There are holes in the flange, and the bolts make the two flanges tight ly connected. The flanges are sealed with gaskets. Flange is divided into threaded connection flange, welded flange and clip flange. Flanges are used in pairs. A gasket is placed between the two flanges an d then bolted. Different flange thicknesses for different pressures use different bolts. Pumps and valves, when connected to the pipeline, part of these equipment also made into the corresponding flange shape, it is also known as flange connection. Joint parts that are bolted at the same time around two planes are generally referred to as "flanges". |

|||||

|

|

|||||

| 2 Flanges Standard | |||||

|

美標:ANSI B16.5、ANSI 16.47 Class 150, 300, 400, 600, 900, 1500, 2500

日標:JIS 5K, 10K, 16K, 20K 德標:DIN2527, 2543, 2545, 2566 2572, 2573, 2576, 2631, 2632, 2633 , 2634, 2638 |

|||||

|

|

|||||

| 3 Flanges Standard | |||||

|

- SO SLIP-ON Flanges

- SC SCREWED Flange - SW SOCKET WELDING Flange - WN WELDING NECK Flange - LJ LAP JOINT Flange - BL BLIND Flange - PL PLATE Flange |

|||||

|

|

|||||

| 4 Flanges Sealing Surface | |||||

|

- RF Raise Face

- FF Flat Face |

|||||

|

|

|||||

| 5 Flanges Material | |||||

|

- Carbon Steel:ASTM A105、 ASTM A350 LF1, LF2, LF3

- Stainless Steel:ASTM A182 F304, 304L, F316, 316L, 304H, 310, 321, 347, 348 - Alloy Steel:ASTM A182 F1, F2, F5, F5a, F9, F11, F12, F21, F22 |

|||||

|

|

|||||

| 6 Ring Joint Facing | |||||

|

Depth L ⋯ + 1/64-0 inch

Width F ⋯ ± 0.008 inch

Pitch Diameter P ⋯ ± 0.005 inch Radius at Bottom r ⋯ max 23° angle ⋯ ± 1/2° |

|||||

|

|

|||||

| 7 Welding Bevels | |||||

|

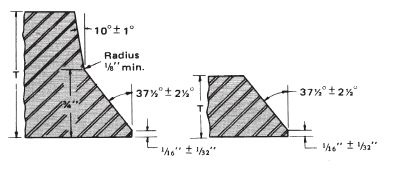

Butt welding ends having thicknesses (T) less than 3/16 inch

may have a slight chamfer or be square; thicknesses of 3/16 to 3/4 inch inclusive shall be beveled 371/2° and the root face (land) shall be 1/16 inch; thicknesses greater than 3/4 inch shall be beveled 371/2° with the thickness beyond 3/4 inch beveled 10°. |

|||||

|

|

|||||

| 8 Orifice Flange | |||||

|

For orifice flanges (not covered by ANSI B16.5) the usual

tolerance on the dimensions 15/16 inch from gasket surface to meter connection tap is ± 1/64 inch for sizes 3 inch and smaller, ± 1/32 inch for sizes 4 inch and larger; regular flange tolerances apply to all other dimensions expect bore tolerances which are 1/2 of 1 percent of nominal bore size. |

|||||

|

|

|||||

Introduction

| Thread, Slip-on, Lap Joint,Socket Welding and Blind | |||||

| Outside Diameter* | O.D. 24 inch or smaller ⋯ ±1/16 inch | ||||

| O.D. over 24 inch ⋯ ±1/8 inch | |||||

| Inside Diameter (bore) |

threaded: to standard gauge limits Slip-on; Lap joint; Socket-welding |

||||

| 10 inch and smaller ⋯ +1/32-0 inch | |||||

| 12 inch and smaller ⋯ +1/16-0 inch | |||||

| Diameter counter bore |

threaded | ||||

| 10 inch and smaller ⋯ +1/32-0 inch | |||||

| 12 inch and large ⋯ +1/16-0 inch | |||||

| Outside Diameter of Hub * |

12 inch and smaller ⋯ +3/32-1/16 inch | ||||

| 14 inch and large ⋯ ±1/8 inch | |||||

| Diameter of contact face |

1/16 inch raised face; 1/4 inch raised face; tongue & grooved |

||||

| Male & Female ⋯ ±1/64 inch | |||||

| Thickness | 18 inch and smaller ⋯ +1/8-0 inch | ||||

| 20 inch and large ⋯ +3/16-0 inch | |||||

| Length Through Hub* |

18 inch and smaller ⋯ +1/8-1/32 inch | ||||

| 20 inch and large ⋯ +3/16-1/16 inch | |||||

| Drilling* | bolt circle ⋯ ±1/16 inch | ||||

| bolt hole spacing ⋯ ±1/32 inch | |||||

| Eccentricity with respectto bore ⋯ 1/32 inch maximum |

|||||

| Welding Neck | |||||

| Outside Diameter* | O.D. 24 inch or smaller ⋯ ±1/16 inch | ||||

| O.D. over 24 inch ⋯ ±1/8 inch | |||||

| Inside Diameter (bore) |

10 inch and smaller ⋯ ±1/32 inch | ||||

| 12 through 18 inch ⋯ ±1/16 inch | |||||

| 20 inch and large ⋯ +1/8-1/16 inch | |||||

| Diameter counter bore |

1/16 inch raised face; 1/4 inch raised face; tougue & grooved |

||||

| Male & Female ⋯ ±1/64 inch | |||||

| Diameter of Hub at Base* |

when x is 24 inch or smaller ⋯ ±1/16 inch | ||||

| when x is over 24 inch ⋯ ±1/8 inch | |||||

| Diameter of Hub at Point of Welding |

5 inch and smaller ⋯ +3/32-1/32 inch | ||||

| 6 inch and large ⋯ +5/32-1/32 inch | |||||

| Thickness | 18 inch and smaller ⋯ +1/8-0 inch | ||||

| 20 inch and large ⋯ +3/16-0 inch | |||||

| Length Through Hub* |

10 inch and smaller ⋯ ±1/16 inch | ||||

| 12 inch and large ⋯ ±1/8 inch | |||||

| Drilling* | bolt circle ⋯ ±1/16 inch | ||||

| bolt hole spacing ⋯ ±1/32 inch | |||||

| Eccentricity with respect to bore ⋯ 1/32 inch maximum |

|||||

| * Not Covered by ANSI B16.5 | |||||

|

Material Specifications ASTM

|

|||||||||||||||||

| Specification or stadards designation |

Symbol | Chemical Requirements | Mechanical Requirements | ||||||||||||||

| C | Mn | P | S | Si | Ni | Cr | Mo | V | Nb | Cu | T.S. | Y.S. | EL. | RED. | HB | ||

| min. | min. | min. | min. | min. | |||||||||||||

| % | % | % | % | % | % | % | % | % | % | % | psi | psi | % | % | max. | ||

| A105 | Max. 0.35 |

Max. 0.60 1.05 |

Max. 0.040 |

Max. 0.050 |

Max. 0.35 |

Max. 0.40 |

Max. 0.30 |

Max. 0.12 |

Max. 0.03 |

Max. 0.02 |

Max. 0.40 |

70,000 | 36,000 | 22 | 30 | 137 ~187 |

|

| A181 | I | 0.35 | 1.10 | 0.050 | 0.050 | 0.35 | 60,000 | 30,000 | 22 | 35 | |||||||

| A181 | I1 | 0.35 | 1.10 | 0.050 | 0.050 | 0.35 | 70,000 | 36,000 | 18 | 24 | |||||||

| A182 | F1 | 0.28 | 0.60 ~0.90 |

0.045 | 0.045 | 0.15 ~0.35 |

0.44 ~0.65 |

70,000 | 40,000 | 25 | 35 | 143 ~192 |

|||||

| A182 | F2 | 0.21 | 0.30 ~0.80 |

0.040 | 0.040 | 0.10 ~0.60 |

0.50 Max |

0.50 ~0.81 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 30 | 143 ~192 |

|||

| A182 | F5 | 0.15 | 0.30 ~0.60 |

0.030 | 0.030 | 0.50 | 0.50 Max |

4.00 ~6.00 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 35 | 143 ~217 |

|||

| A182 | F5a | 0.25 | 0.60 | 0.040 | 0.030 | 0.50 | 4.00 ~6.00 |

0.44 ~0.65 |

90,000 | 65,000 | 22 | 50 | 187 ~248 |

||||

| A182 | F9 | 0.15 | 0.30 ~0.60 |

0.030 | 0.030 | 0.50 ~1.00 |

8.00 ~10.00 |

0.90 ~1.10 |

85,000 | 55,000 | 20 | 40 | 179 ~207 |

||||

| A182 | F11 | 0.10 ~0.20 |

0.30 ~0.80 |

0.040 | 0.040 | 0.05 ~1.00 |

1.00 ~1.50 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 30 | 143 ~207 |

||||

| A182 | F12 | 0.10 ~0.20 |

0.30 ~0.80 |

0.040 | 0.040 | 0.10 ~0.60 |

8.00 ~10.00 |

0.44 ~0.65 |

70,000 | 40,000 | 20 | 30 | 143 ~207 |

||||

| A182 | F21 | 0.15 | 0.30 ~0.60 |

0.040 | 0.040 | 0.50 | 2.65 ~3.35 |

0.80 ~1.06 |

75,000 | 45,000 | 20 | 30 | 156 ~207 |

||||

| A182 | F22 | 0.15 | 0.30 ~0.60 |

0.040 | 0.040 | 0.50 | 2.00 ~2.50 |

0.87 ~1.13 |

75,000 | 45,000 | 20 | 30 | 156 ~207 |

||||

| A182 | F304 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 8.00 ~11.00 |

18.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F304H | 0.04 ~0.10 |

2.00 | 0.040 | 0.030 | 1.00 | 8.00 ~11.00 |

18.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F304L | 0.035 | 2.00 | 0.040 | 0.030 | 1.00 | 8.00 ~13.00 |

18.00 ~20.00 |

70,000 | 25,000 | 30 | 50 | |||||

| A182 | F310 | 0.15 | 2.00 | 0.040 | 0.030 | 1.00 | 19.00 ~20.00 |

24.00 ~26.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F316 | 0.08 | 2.00 | 0.040 | 0.030 | 1.00 | 10.00 ~14.00 |

16.00 ~18.00 |

2.00 ~3.00 |

75,000 | 30,000 | 30 | 50 | ||||

| A182 | F316H | 0.04 ~0.10 |

2.00 | 0.040 | 0.030 | 1.00 | 10.00 ~14.00 |

16.00 ~18.00 |

2.00 ~3.00 |

75,000 | 30,000 | 30 | 50 | ||||

| A182 | F316L | 0.035 | 2.00 | 0.040 | 0.030 | 1.00 | 10.00 ~15.00 |

16.00 ~18.00 |

2.00 ~3.00 |

70,000 | 25,000 | 30 | 50 | ||||

| A182 | F321 | 0.08 | 2.00 | 0.030 | 0.030 | 1.00 | 9.00 ~12.00 |

17.00 ~Min. |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F347 | 0.08 | 2.00 | 0.030 | 0.030 | 1.00 | 9.00 ~13.00 |

17.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A182 | F348 | 0.08 | 2.00 | 0.030 | 0.030 | 1.00 | 9.00 ~13.00 |

17.00 ~20.00 |

75,000 | 30,000 | 30 | 50 | |||||

| A350 | LF1 | 0.30 | 0.75 ~1.05 |

0.035 | 0.040 | 0.15 ~0.30 |

60,000 ~85,000 |

30,000 | 25 | 38 | |||||||

| A350 | LF2 | 0.30 | 1.35 | 0.035 | 0.040 | 0.15 ~0.30 |

70,000 ~95,000 |

36,000 | 22 | 30 | |||||||

| A350 | LF3 | 0.20 | 0.90 | 0.035 | 0.040 | 0.20 ~0.35 |

3.25 ~3.75 |

70,000 ~95,000 |

37,500 | 22 | 35 | ||||||

|

Approx. Weight List ANSI B16.5 Forged Flanges Unit Pound And (kg)

|

|||||||

| Class | Nominal Pipe Size |

Slip on Type | Blind | Welding Neck |

|||

| Slip On | Screwed | Socket | Lap Joint | ||||

| 150 lb | 1/2 | 1 (0.45) | 1 (0.45) | 2 (0.91) | 2 (0.91) | 2 (0.91) | 2 (0.91) |

| 3/4 | 11/2 (0.68) | 11/2 (0.68) | 2 (0.91) | 21/2 (0.91) | 2 (0.91) | 2 (0.91) | |

| 1 | 2 (0.91) | 2 (0.91) | 2 (0.91) | 2 (0.91) | 2 (0.91) | 21/2 (1.41) | |

| 11/4 | 21/2 (1.41) | 21/2 (1.41) | 3 (1.36) | 31/2 (1.36) | 3 (1.36) | 21/2 (1.41) | |

| 11/2 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 4 (1.81) | |

| 2 | 5 (2.18) | 5 (2.27) | 5 (2.27) | 5 (2.27) | 4 (1.82) | 6 (2.72) | |

| 21/2 | 8 (3.45) | 8 (3.45) | 7 (3.18) | 8 (3.63) | 7 (3.18) | 10 (4.45) | |

| 3 | 9 (4.01) | 10 (4.54) | 8 (3.63) | 9 (4.09) | 9 (4.09) | 111/2 (5.22) | |

| 31/2 | 11 (4.99) | 12 (5.45) | 11 (4.99) | 11 (4.99) | 13 (5.90) | 12 (5.45) | |

| 4 | 13 (5.63) | 13 (5.9) | 13 (5.90) | 13 (5.90) | 17 (7.72) | 161/2 (7.49) | |

| 5 | 15 (6.74) | 15 (6.81) | 15 (6.81) | 15 (6.81) | 20 (9.08) | 21 (9.53) | |

| 6 | 17 (7.90) | 191/2 (8.85) | 19 (8.63) | 19 (8.63) | 27 (12.26) | 26 (11.80) | |

| 8 | 28 (12.90) | 30 (13.62) | 30 (13.62) | 30 (13.62) | 47 (21.34) | 42 (19.07) | |

| 10 | 40 (17.60) | 41 (18.61) | 43 (19.52) | 43 (19.52) | 67 (30.42) | 54 (24.52) | |

| 12 | 61 (27.69) | 65 (29.51) | 64 (29.06) | 64 (29.06) | 123 (45.00) | 88 (39.95) | |

| 14 | 83 (37.68) | 85 (38.59) | 85 (38.59) | 99 (44.95) | 139 (63.11) | 114 (51.76) | |

| 16 | 106 (48.12) | 93 (42.22) | 93 (42.22) | 128 (58.11 | 187 (84.90) | 142 (64.47) | |

| 18 | 109 (49.49) | 120 (54.48) | 120 (54.48) | 146 (66.28) | 217 (98.52) | 165 (74.90) | |

| 20 | 148 (67.19) | 155 (70.37) | 155 (70.37) | 185 (83.99) | 283 (128.48) | 197 (89.44) | |

| 24 | 204 (92.62) | 210 (95.34) | 210 (95.34) | 260 (118.04) | 415 (188.41) | 268 (121.67) | |

| 300 lb | 1/2 | 11/2 (0.68) | 11/2 (0.68) | 3 (1.36) | 3 (1.36) | 2 (0.91) | 2 (0.91) |

| 3/4 | 21/2 (1.14) | 21/2 (1.14) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | |

| 1 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 4 (1.82) | 4 (1.82) | |

| 11/4 | 41/2 (2.04) | 41/2 (2.04) | 4 (1.82) | 41/2 (2.04) | 6 (2.72) | 5 (2.72) | |

| 11/2 | 61/2 (2.95) | 61/2 (2.95) | 6 (2.72) | 61/2 (2.95) | 7 (3.18) | 7 (3.18) | |

| 2 | 7 (3.18) | 7 (3.18) | 7 (3.18) | 7 (3.18) | 8 (3.63) | 8 (3.63) | |

| 21/2 | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | 12 (5.45) | 12 (5.45) | |

| 3 | 13 (5.90) | 14 (6.36) | 13 (5.90) | 141/2 (6.58) | 16 (7.26) | 18 (8.17) | |

| 31/2 | 16 (7.26) | 16 (7.26) | 17 (7.72) | 17 (7.72) | 21 (9.53) | 20 (9.1) | |

| 4 | 231/2 (10.67) | 24 (10.90) | 22 (9.99) | 24 (10.90) | 28 (12.71) | 261/2 (12.03) | |

| 5 | 29 (13.17) | 31 (14.07) | - | 28 (12.71) | 37 (16.80) | 36 (16.34) | |

| 6 | 36 (16.34) | 36 (16.34) | - | 39 (17.71) | 48 (21.79) | 45 (20.43) | |

| 8 | 56 (25.42) | 56 (25.42) | - | 58 (26.33) | 79 (35.87) | 69 (31.33) | |

| 10 | 77 (34.96) | 80 (36.32) | - | 91 (41.31) | 122 (55.39) | 100 (45.4) | |

| 12 | 113 (51.30) | 110 (49.94) | - | 139 (63.11) | 183 (83.08) | 142 (64.47) | |

| 14 | 159 (72.19) | 164 (74.46) | - | 189 (85.81) | 241 (109.41) | 206 (93.52) | |

| 16 | 210 (95.34) | 220 (99.88) | - | 240 (108.96) | 315 (143.01) | 249 (113.05) | |

| 18 | 253 (114.86) | 280 (127.12) | - | 305 (138.47) | 414 (187.96) | 306 (138.92) | |

| 20 | 307 (139.38) | 325 (147.55) | - | 375 (170.25) | 515 (233.81) | 369 (167.53) | |

| 24 | 490 (222.46) | 490 (222.46) | - | 530 (240.62) | 800 (363.2) | 519 (235.63) | |

|

Unit Pound And (kg)

|

||||||

| Class | Nominal Pipe Size |

Slip on Type | Blind | Welding Neck |

||

| Slip On | Screwed | Lap Joint | ||||

| 400 lb | 1/2 | 2 (0.91) | 2 (0.91) | 3 (1.36) | 2 (0.91) | 3 (1.36) |

| 3/4 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 31/2 (1.59) | |

| 1 | 31/2 (1.59) | 31/2 (1.59) | 4 (1.82) | 4 (1.82) | 4 (1.82) | |

| 11/4 | 41/2 (2.04) | 41/2 (2.04) | 6 (2.72) | 6 (2.72) | 51/2 (2.50) | |

| 11/2 | 61/2 (2.95) | 61/2 (2.95) | 7 (3.18) | 8 (3.63) | 8 (3.63) | |

| 2 | 8 (3.63) | 8 (3.63) | 9 (4.09) | 10 (4.54) | 10 (4.54) | |

| 21/2 | 12 (5.45) | 12 (5.45) | 12 (5.45) | 15 (6.81) | 14 (6.36) | |

| 3 | 15 (6.81) | 15 (6.81) | 15 (6.81) | 20 (9.08) | 18 (8.17) | |

| 31/2 | 21 (9.53) | 21 (9.53) | 20 (9.08) | 29 (13.17) | 26 (11.80) | |

| 4 | 24 (10.9) | 24 (10.9) | 25 (11.35) | 33 (14.98) | 30 (13.62) | |

| 5 | 31 (14.07) | 31 (14.07) | 29 (13.17) | 44 (19.98) | 39 (17.71) | |

| 6 | 39 (17.71) | 39 (17.71) | 42 (19.07) | 61 (27.69) | 49 (22.45) | |

| 8 | 63 (28.60) | 63 (28.60) | 64 (29.06) | 100 (45.4) | 78 (35.41) | |

| 10 | 91 (41.31) | 91 (41.31) | 112 (50.85) | 155 (70.37) | 110 (49.94) | |

| 12 | 129 (58.57) | 129 (58.57) | 152 (69.01) | 226 (102.60) | 160 (72.64) | |

| 14 | 191 (86.71) | 191 (86.71) | 210 (95.34) | 310 (140.74) | 233 (105.78) | |

| 16 | 253 (114.86) | 253 (114.86) | 280 (127.12) | 398 (180.69) | 194 (133.78) | |

| 18 | 310 (140.74) | 310 (140.74) | 345 (156.63) | 502 (227.91) | 360 (163.44) | |

| 20 | 378 (171.61) | 378 (171.61) | 420 (190.68) | 621 (281.93) | 445 (202.03) | |

| 24 | 539 (244.71) | 539 (244.71) | 615 (279.21) | 936 (424.94) | 640 (290.56) | |

| 600 lb | 1/2 | 2 (0.91) | 2 (0.91) | 3 (1.36) | 2 (0.91) | 3 (1.36) |

| 3/4 | 3 (1.36) | 3 (1.36) | 3 (1.36) | 3 (1.36) | 31/2 (1.59) | |

| 1 | 31/2 (1.59) | 31/2 (1.59) | 4 (1.82) | 4 (1.82) | 4 (1.82) | |

| 11/4 | 41/2 (2.04) | 41/2 (2.04) | 6 (2.72) | 6 (2.72) | 51/2 (2.50) | |

| 11/2 | 61/2 (2.95) | 61/2 (2.95) | 7 (3.18) | 8 (3.63) | 8 (3.63) | |

| 2 | 8 (3.63) | 8 (3.63) | 9 (4.09) | 10 (4.54) | 10 (4.54) | |

| 21/2 | 12 (5.45) | 12 (5.45) | 12 (5.45) | 15 (6.81) | 14 (6.36) | |

| 3 | 15 (6.81) | 15 (6.81) | 15 (6.81) | 20 (9.08) | 18 (8.17) | |

| 31/2 | 21 (9.53) | 21 (9.53) | 20 (9.08) | 29 (13.17) | 26 (11.80) | |

| 4 | 33 (14.98) | 33 (14.98) | 36 (16.34) | 41 (18.61) | 37 (16.80) | |

| 5 | 63 (28.60) | 63 (28.60) | 63 (28.60) | 68 (30.87) | 68 (30.87) | |

| 6 | 80 (36.32) | 80 (36.32) | 78 (35.41) | 86 (39.04) | 73 (33.14) | |

| 8 | 97 (44.04) | 97 (44.04) | 112 (50.85) | 139 (63.11) | 112 (50.85) | |

| 10 | 177 (80.36) | 177 (80.36) | 195 (88.53) | 231 (104.87) | 189 (85.81) | |

| 12 | 215 (97.61) | 215 (97.61) | 240 (108.96) | 295 (133.93) | 226 (102.60) | |

| 14 | 259 (117.59) | 259 (117.59) | 290 (131.66) | 378 (148.91) | 347 (157.54) | |

| 16 | 366 (166.16) | 366 (166.16) | 400 (181.6) | 527 (239.26) | 481 (218.37) | |

| 18 | 476 (216.10) | 476 (216.10) | 469 (212.93) | 665 (301.91) | 555 (251.97) | |

| 20 | 612 (277.85) | 612 (277.85) | 604 (274.22) | 855 (388.17) | 690 (313.26) | |

| 24 | 876 (397.70) | 876 (397.70) | 866 (393.16) | 1175 (533.45) | 977 (443.56) | |

|

Unit Pound And (kg)

|

||||||

| Class | Nominal Pipe Size |

Slip on Type | Blind | Welding Neck |

||

| Slip On | Screwed | Lap Joint | ||||

| 900 lb | 1/2 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 4 (1.82) | 7 (3.18) |

| 3/4 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 6 (2.72) | 7 (3.18) | |

| 1 | 71/2 (3.41) | 71/2 (3.41) | 9 (4.09) | 9 (4.09) | 81/2 (3.86) | |

| 11/4 | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | |

| 11/2 | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | |

| 2 | 22 (9.99) | 22 (9.99) | 25 (11.35) | 25 (11.35) | 24 (10.90) | |

| 21/2 | 36 (16.34) | 36 (16.34) | 35 (15.89) | 35 (15.89) | 36 (16.34) | |

| 3 | 31 (14.07) | 31 (14.07) | 20 (13.62) | 32 (14.53) | 29 (13.17) | |

| 4 | 53 (24.06) | 53 (24.06) | 51 (23.15) | 54 (24.52) | 51 (23.15) | |

| 5 | 83 (37.68) | 83 (37.68) | 81 (36.77) | 87 (39.50) | 86 (39.04) | |

| 6 | 108 (49.03) | 108 (49.03) | 105 (47.67) | 113 (51.30) | 110 (49.94) | |

| 8 | 172 (78.09) | 172 (78.09) | 188 (85.35) | 197 (89.44) | 187 (84.90) | |

| 10 | 245 (111.23) | 245 (111.23) | 277 (125.76) | 290 (131.66) | 268 (121.67) | |

| 12 | 326 (148.00) | 326 (148.00) | 371 (168.43) | 413 (187.50) | 372 (168.89) | |

| 14 | 380 (172.52) | 380 (172.52) | 397 (180.24) | 494 (224.28) | 567 (255.15) | |

| 16 | 459 (208.39) | 459 (208.39) | 488 (221.55) | 619 (281.03) | 685 (310.99) | |

| 18 | 647 (293.74) | 647 (293.74) | 670 (304.18) | 880 (399.52) | 924 (419.50) | |

| 20 | 792 (359.57) | 792 (359.57) | 868 (394.07) | 1107 (502.58) | 1164 (528.46) | |

| 24 | 1480 (671.92) | 1480 (671.92) | 1659 (753.19) | 2099 (952.95) | 2107 (956.58) | |

| 1500 lb | 1/2 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 4 (1.82) | 7 (3.18) |

| 3/4 | 6 (2.72) | 6 (2.72) | 9 (4.09) | 6 (2.72) | 7 (3.18) | |

| 1 | 71/2 (3.41) | 71/2 (3.41) | 9 (4.09) | 9 (4.09) | 81/2 (3.86) | |

| 11/4 | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | 10 (4.54) | |

| 11/2 | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | 14 (6.36) | |

| 2 | 22 (9.99) | 22 (9.99) | 25 (11.35) | 25 (11.35) | 24 (10.90) | |

| 21/2 | 36 (16.34) | 36 (16.34) | 35 (15.9) | 35 (15.89) | 36 (16.34) | |

| 3 | 48 (21.79) | 48 (21.79) | 47 (21.3) | 48 (21.79) | 48 (21.79) | |

| 4 | 73 (33.14) | 73 (33.14) | 75 (34.05) | 73 (33.14) | 69 (31.33) | |

| 5 | 132 (59.93) | 132 (59.93) | 138 (62.65) | 142 (64.47) | 132 (59.93) | |

| 6 | 164 (74.46) | 164 (74.46) | 170 (77.18) | 159 (72.19) | 164 (74.46) | |

| 7 | 258 (117.13) | 258 (117.13) | 286 (129.84) | 302 (137.11) | 273 (123.94) | |

| 10 | 436 (197.94) | 436 (197.94) | 485 (220.19) | 507 (230.18) | 454 (206.12) | |

| 12 | 667 (302.82) | 667 (302.82) | 749 (340.05) | 775 (351.85) | 690 (313.26) | |

| 2500 lb | 1/2 | 7 (3.18) | 7 (3.18) | 7 (3.18) | 7 (3.18) | 8 (3.63) |