- Home

- >

- Product

- >

- IEC/UL/TS Explosion-proof fittings

- >

- Junction Box GC

-

-

Junction Box GC

ApplicationG* series Junction Box are installed in conduit systems within hazardous areas to: 1 Accommodates wiring devices and provides opening to splice, tap , or pull conductors. 2 Provide access to conductors for maintenance and future system changes.

Specification

| Explosion proof execution | EX db IIC T6 Gb,EX tb IIIC T80ºC Db IP66 |

| Certificate issued by | TUV Rheinland /TS mark |

| Material | Ductile Iron-Powder Paint / Ductile Iron-Hot Dip Galvanized / A luminum / Stainless Steel 304 / Stainless Steel 316 |

| Designation part number system | ||||

| 1 | 2 | 3 | 4 | 5 |

| Certification Unit | Name of fitting | Hub Size | Thread Standard | Material |

| 1 Certification Unit / Code | |||||

| International Electrotechnical Commission / IEC | |||||

| 2 Name of fitting / Code | |||||

| GA / GC / GL / GT /GX / GLB | |||||

| 2 Hub / Code | |||||||||

| Hub Size | 1/2" | 3/4" | 1 | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" |

| Code | 050 | 075 | 100 | 125 | 150 | 200 | 250 | 300 | 400 |

| 3 Thread Standards / Code | |||||

| Thread Standards | Code | ||||

| NPT | N | ||||

| 4 Material / Finish / Code | ||||||

| Material | Finish | Code | ||||

| Ductile iron | Powder Paint | E2 | ||||

| SUS304 | S4 | |||||

| Ductile iron | Hot Dip Galvanized | H | ||||

| SUS316 | S6 | |||||

| Aluminum | AL | |||||

| Example | ||||

| IEC | GA | 075 | N | E2 |

| Certification Unit | Name of fitting | Hub Size | Thread Standard | Material |

| IEC | GA TYPE Junction BOX |

3/4" | NPT | Powder Paint |

| IEC | GT | 200 | N | H |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material |

| IEC | GT TYPE Junction BOX |

2" | NPT | Ductile iron |

Introduction

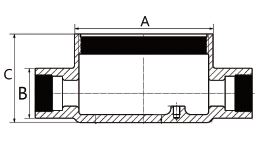

| 規格 | Dimensions (mm) | ||

| Hub Size | A | B | C |

| 1/2" | 96 | 33 | 60 |

| 3/4" | 96 | 38 | 60 |

| 1" | 96 | 44 | 60 |

| 1-1/4" | 115 | 54.5 | 70 |

| 1-1/2" | 146 | 63 | 95 |

| 2" | 146 | 75 | 107 |

| · Tolerance: ±5% | |||

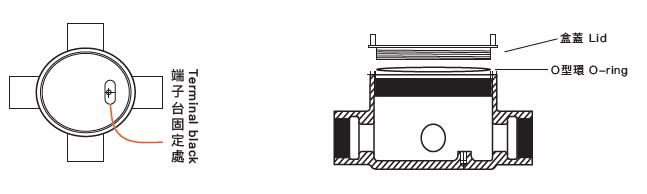

| Instruction of GA / GC / GL / GT /GX / GLB | ||||

| A |

Open the lid of the box after finishing the relevant piping.

|

|||

| B | Loosen the internal screws, and assemble the terminal blocks with Increased safety certified terminal blocks, and then connect the wiring. |

|||

| C | Tighten the lid back after finishing relevant piping works, and be aware of the place of the washer, must to tighten the lid completely. |

|||

Product Consultation