- Home

- >

- Product

- >

- IEC/UL/TS Explosion-proof fittings

- >

- Sealing Fittings EYM

-

-

Sealing Fittings EYM

ApplicationSealing Fitting mainly installed in the lamps, or distribution box into the box work Its main job is to block the sparks generated inside the box or lamp to achieve explosion-proof effect

Specification

| Explosion proof execution | EX db IIC Gb,EX tb IIIC Db IP66 or IP65 or IP64 IP65: 2-1/2"~3" , IP64: 4" , , IP66 for other size. |

| Certificate issued by | TÜV Rheinland /TS mark |

| Material | Ductile Iron-Powder Paint / Ductile Iron-Hot Dip Galvanized Aluminum / Stainless Steel 304 / Stainless Steel 316 |

| Designation part number system | ||||

| 1 | 2 | 3 | 4 | 5 |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material |

| 1 Certification Unit / Code | |||||

| International Electrotechnical Commission / IEC | |||||

| 2 Name of fitting / Code | |||||

| EYF / EYM / EYD / EYDM | |||||

| 2 Hub / Code | |||||||||

| Hub Size | 1/2" | 3/4" | 1 | 1-1/4" | 1-1/2" | 2" | 2-1/2" | 3" | 4" |

| Code | 050 | 075 | 100 | 125 | 150 | 200 | 250 | 300 | 400 |

| 3 Thread Standards / Code | |||||

| Thread Standards | Code | ||||

| NPT | N | ||||

| 4 Material / Finish / Code | ||||||

| Material | Finish | Code | ||||

| Ductile iron | Powder Paint | E2 | ||||

| SUS304 | S4 | |||||

| Ductile iron | Hot Dip Galvanized | H | ||||

| SUS316 | S6 | |||||

| Aluminum | AL | |||||

| Example | ||||

| IEC | EYF | 075 | N | E2 |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material |

| IEC | EYF TYPE | 3/4" | NPT | Powder Paint |

| IEC | EYD | 250 | N | H |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material |

| IEC | EYD TYPE | 2~1/2" | NPT | Ductile iron |

Introduction

| 規格 | Dimensions (mm) | |

| Hub Size | A | B |

| 1/2" | 86 | 32 |

| 3/4" | 97 | 40 |

| 1" | 112 | 45 |

| 1-1/4" | 133 | 56 |

| 1-1/2" | 143 | 60.6 |

| 2" | 166 | 73.7 |

| 2-1/2" | 191 | 89 |

| 3" | 214 | 105 |

| 4" | 252 | 133 |

| · Tolerance: ±5% | ||

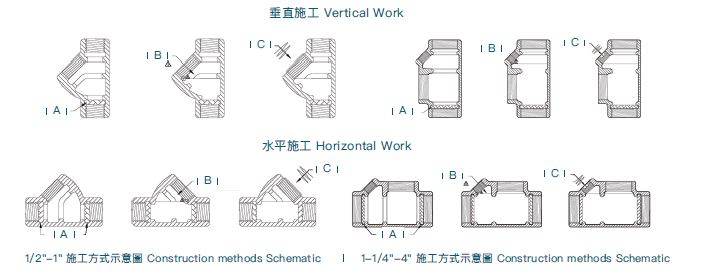

| Vertical Work | |

| A |

Loosen A and B from lateral sides of EYF/EYD. Fill up bottom entrance completely

with packing fibers. |

| B | Blend sealing compound and water into solvent-based sealing compound in accordance with instructions of each brand. After finishing filling of packing fibers, tighten on A in advanced to avoid solvent-based sealing compound from flowing over when filling the sealing compound. Add solvent-based sealing compound into EYF/EYD via B until the amount reaches the place of first threads in B. |

| C | Tighten plug B to complete the work. |

| Horizontal Work- | |

| A |

Loosen A and B from lateral sides of EYF/EYD. Fill up entrances on both sides

completely with sealing compound. |

| B | Blend sealing compound and water into solvent-based sealing compound in accordance with instructions of each brand. After finishing filling of packing fibers, pour the solvent-based sealing compound into EYF/EYD via A until the solvent touches the first place of A. |

| C | Tighten plug A and B back onto EYF/EYD to complete the work. |

NOTE:Both of above sealing compound and packing fibers must pass the relevant certification of

explosion proof test before being applied on this product.

Product Consultation