- Home

- >

- Product

- >

- IEC/UL/TS Explosion-proof fittings

- >

- Non-Armoured Cable Gland-Barrier type NCC

-

-

Non-Armoured Cable Gland-Barrier type NCC

ApplicationThe main function of the explosion-proof cable fixing connector is to use the cable into the distribution box or into the explosion-proof lighting device.

Specification

| Explosion proof execution | EX db IIC Gb,Ex eb IIC Gb,EX t b IIIC Db IP66 |

| Certificate issued by | TÜV Rheinland / TS mark |

| Material | Brass / Brass-Nickel Plating / Steel-Zinc Electroplated / Stain less Steel 304 / Stainless Steel 316 |

| Designation part number system | ||||

| 1 | NCC | 2 | 3 | 4 |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material |

| 1 Certification Unit / Code | |||||

| International Electrotechnical Commission / IEC | |||||

| 2 Hub Size / Code lnch | |||||||||||

| Hub Size | 1/2"A | 1/2"B | 3/4" | 1 | 1-1/4" | 1-1/2" | 2"A | 2"B | 2-1/2"A | 2-1/2"B | 3" |

| Code | 050A | 050B | 075 | 100 | 125 | 150 | 200A | 200B | 250A | 250B | 300 |

| Metric | |||||||||||

| Hub Size | M20A | M20B | M25 | M32 | M40 | M50A | M50B | M63A | M63B | M75A | M75B |

| Code | 20A | 20B | 25 | 32 | 40 | 50A | 50B | 63A | 63B | 75A | 75B |

| 3 Thread Standards / Code | |||||

| Thread Standards | Code | ||||

| NPT | N | ||||

| Metric Fine Thread | M | ||||

| 4 Material / Finish / Code | |||||

| Material | Code | ||||

| Brass | B | ||||

| SUS304 | S4 | ||||

| Brass / Nickel Plating | BN | ||||

| SUS316 | S6 | ||||

| Steel / Zinc Electroplated | E | ||||

| Example | ||||

| IEC | NCC | 075 | M | BN |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material |

| IEC | Non-Armoured Cable Gland-Barrier type | 3/4" | NPT | Brass / Nickel Plating |

| IEC | NCC | 25 | M | S4 | |

| Certification Unit | Name of fitting | Hub Size & Type | Thread Standard | Material | |

| IEC | Non-Armoured Cable Gland-Barrier type | M25 |

|

SUS304 | |

Introduction

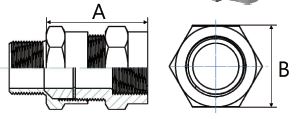

| Hub Size | Dimensions (mm) | 電纜外徑 | |||

| Metric | Inch | A | B | Overall Cable Diameter | |

| M20A | 1/2"A | 58 | 32 | 4~8.9 | |

| M20B | 1/2"B | 58 | 32 | 9~13.9 | |

| M25 | 3/4 | 58 | 40 | 14~19.9 | |

| M32 | 1" | 58 | 46 | 20~25.3 | |

| M40 | 1-1/4" | 60 | 53 | 25~31.8 | |

| M50A | 1-1/2" | 64 | 60 | 31~37.9 | |

| M50B | 2"A | 71 | 75 | 38~44.8 | |

| M63A | 2"B | 71 | 75 | 42~48.8 | |

| M63B | 2-1/2"A | 80 | 90 | 49~55.8 | |

| M75A | 2-1/2"B | 80 | 90 | 55~61.7 | |

| M75B | 3" | 82 | 97 | 61.5~68.7 | |

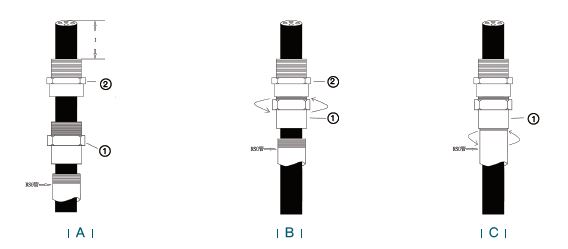

| Instruction of Non-Armoured Cable Gland | ||||

| A |

Pull sufficient length "I" of cable through conduit/cable gland to suit

equipment. |

|||

| B | Unless already screwed into the equipment, hold the entry" 2" in position with a spanner/wrench to prevent rotation and tighten the backnut "1" using a wrench/spanner until resistance is felt between the seal and cable. Then turn the back nut through a further half to one full turn to complete the inner seal. |

|||

| C | With a spanner/wrench to prevent rotation and tighten the backnut "1", screw pre-threaded conduit into cable gland and tighten with spanner |

|||

Product Consultation